False measurements are when the device shows a measurement while not being in contact with a component. The device will stop showing a measurement value when the tips are removed. False measurements will cause the device to continue displaying a measurement and not turn off, leading to the battery being drained.

There are a few reasons as to why the device is showing a false measurement. This could include the tips being misaligned or shifted during transportation or if the device has been dropped or mishandled. Replacing the tips with a new set may also cause false readings. Generally, these false measurements are caused by metal or plastic debris caught between the tips and arms of the device and can be fixed with these easy steps:

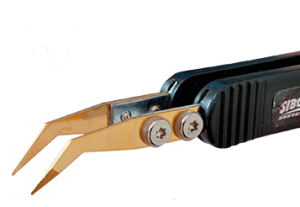

- Start by removing the tips and cleaning the arms with isopropyl and a soft cloth or gauze to remove any extra debris. Reinstall the tips to the device. If the device is still showing a reading, remove the tips and continue to step two.

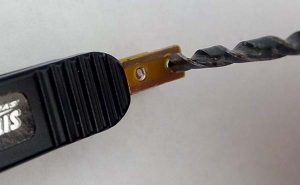

- Try removing any excess flex cable from in or around the screw-holes. Gently rotate a drill bit by hand or use a Philips head screwdriver that is twice the size of the hole. This will scrape away any extra plastic and gold from the flex cable. The red circles in the image below shows where interference can occur.

- Sometimes bits of metal remain stuck in the threads from assembly. These bits can be removed using a tap or one of the screws to clear the threads. Tighten and remove a few times.

- Cleaning the screws may also help. Sometimes debris can be stuck between the threads.

- If all else fails, make sure there is no metal bits stuck under the flex cable around the screw holes. Very rarely does metal get between these two pieces, but it can create false measurements. Always try scraping away extra flex cable first. Use sharp tweezers to remove any visible metal pieces without tearing or damaging the flex cable.

NOTE: Removing the flex cable will damage the glue and may cause issues when re-adhering the flex cable which can impact the accuracy of the measurements.

- Make sure to clean away any residual plastic or metal using isopropyl and a soft cloth or gauze before reinstalling the tips.

If these steps do not remove the false readings, please contact Siborg Systems Inc.

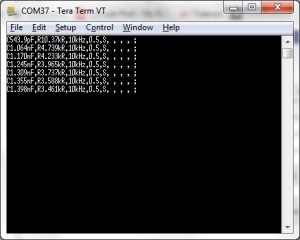

-wire is best for the older models, including the ST-1, ST-2, ST-3 and STIC. These older models used a 2-wire connection in the handles of the device and could not be properly tested with the 4-wire terminal. This new calibration unit will allow all models to be tested and calibrated.” says the Director of Research and Development at Siborg, Michael Obrecht.

-wire is best for the older models, including the ST-1, ST-2, ST-3 and STIC. These older models used a 2-wire connection in the handles of the device and could not be properly tested with the 4-wire terminal. This new calibration unit will allow all models to be tested and calibrated.” says the Director of Research and Development at Siborg, Michael Obrecht.